Replacing the heating elements on the Pelton Crane Models is a pretty straight-forward procedure.

Tools Required: Standard Screwdriver/Wire Strippers

Warning: Turn Unit Off & Unplug From Outlet Before Proceeding

Disassembly

- Remove the cabinet by removing the cabinet screws on both sides of the autoclave. Depending on the model you have, there will be 3 or 4 on each side, towards the bottom.

- Pick up the rear of the cabinet & slide it forward slightly (there is a 1/2 inch lip on the front of the unit that has to be cleared before you can remove it). Then lift the cabinet off and set it aside.

- Lift off the insulation blanket and set it inside the cabinet so it too is out of the way.

Tip: → To make reassembly smoother, make a mental note which end of the insulation blanket goes towards the front.

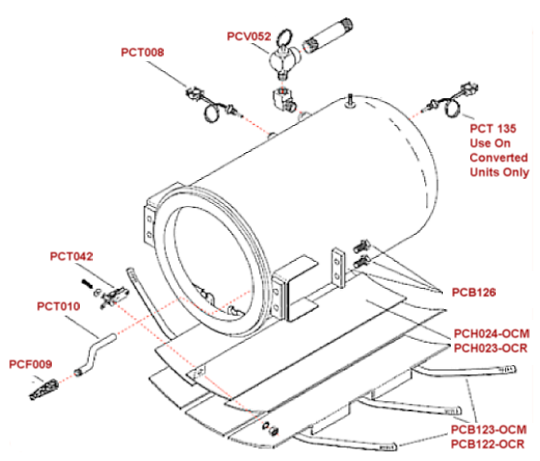

Surrounding the chamber are 3 bands (similar to oversized hose clamps). These bands are what holds the heating elements in place against the chamber walls.

Tip: → Before proceeding, take a pencil and outline the top corners and left edge of the first heating element on the chamber and both sides of the bands. These marks will greatly simplify the re-installation process.

- Unscrew the bands with a screwdriver, by turning in a counter clockwise direction. Unscrew them completely so the ends are free.

Once all 3 bands are loosened, the heating elements will drop to the bottom of the platform. Pull the bands away from the heating elements and set them aside.

Pull the heating elements towards you (the wires are still attached, so you will only be able to pull them out so far before disconnecting the wires.

- Tip → It's a good idea to take a moment now and mark or tag the wires you remove so you know where they come from. This will greatly speed up the reassembly.

- Under the heating elements is a backup plate. This functions as a bracket assembly to hold the elements in place and give them some protection.

Remove the heating element(s) that are being replaced by unscrewing the screws holding the wire at each end of the element by turning them in a counterclockwise direction.

- Inspect all wires. Look for cracks, breaks or burnt spots. If any are found, replace that wire. We include 3 feet of new high temperature wire with every element.

Reassembly

- Inspect & Clean the outside of the chamber.

- Replace the old element with the new. (If there is a copper plate under the old element being replaced, discard it).

- Attach the wires to the new element in the same fashion as the old element. Push the assembly back under the chamber.

Now slide the pointed end of the bands under the bracket assembly holding the heating elements and around the chamber and reconnect any other wires you may have disconnected.

- Lift up on the assembly and start each band by pushing the pointed end into the head with the screw and turning the screws a few times to hold it in place.

Then tighten each band until all slack is gone and the bracket assembly is snug but still movable. Line up the bands with your pencil marks and the heating first element fits the outline you made previously.

- Tighten the bands sequentially. The same amount of torque should be appliled to all 3 bands (40 lbs maximum).

- Perform final inspection. Verify that the curvature of the heater(s) matches the chamber and no gaps exist.

- Now plug the unit back up and run it through a cycle.

Note: Heating element contains a mica material with an adhesive that may cause a non-toxic smoke when initially energized.

Heater installation should be performed in a well ventilated area. Also, allow 10 to 15 minutes "burn in" time.

After "burn in" time, retighten the tie down bands. This will ensure better surface contact between heater and chamber.

Excessive tightening of screws may cause heater to fail.

It is recommended that the overtemperature switch (which mounts on flip up tab on heater) be changed whenever the heaters are changed.

If the autoclave functions as normal, turn it off and unplug it. Replace the insulation and replace the cabinet.