SECTION 3-COMPONENTS BY FUNCTION

SECTION 3 - VALIDATOR PLUS DECSCRIPTION OF COMPONENTS BY FUNCTIONS

DOOR LOCK

DOOR LOCKThe door locking mechnaism prevents opening the door while the unit is pressurized. When the internal pressure equals atmospheric pressure, the door may be opened.

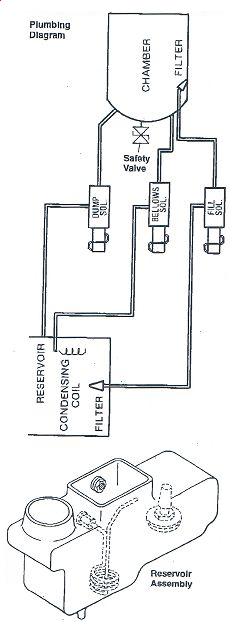

SAFETY VALVE

The safety valve, located on the top rear of the chamber, serves as backup protection in case of excessive pressure in the chamber. The safety valve opens only if chamber pressure exceeds 262 kPa (38PSI)

WARNING: The safety valve limits the maximum pressure to 262 kPa (38PSI). When replacing the safety valve, use only the type for which the unit was originally certified.

FILL/VENT SOLENOID

The fill/vent solenoid serves two purposes under software control:

- When in the fill process this solenoid allows water to enter the chamber and reservoir. It is open for a minimum of one minute during this process. It will be open for longer periods of time as each successive cycle is run based on the amount of reservoir in the reservoir.

If there is pressure in the unit at the time the fill cycle starts, then this this timer will be displayed until al pressure has been exhausted in order to facilitate rapid cycling of the unit. - When in the venting process, and the pressure is between 40 and 20 kPa, the fill solenoid opens to extract the water from the chamber through the bottom of the reservoir.

This solenoid is under software control and also serves two purposes:

- When in the venting process, this solenois is used to exhaust the pressure from the working value to 40 kPa.

- Whe in the air-bleeding process, this solenoid is used as an electronic bellows to remove the aur from the chamber in order to obtain saturated steam conditions

This solenoid is under software control. Its primary purpose is to rapidly exhasut residual chamber pressure. Normally, during the venting process, it will be opened at 20kPa, but it may be oopened during the filling process to exhaust residual pressures.

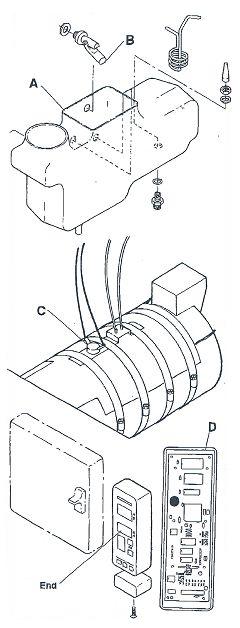

RESERVOIR ASSEMBLY

The reservoir assembly holds water for filling the autoclave chamber. The condensing coil in the assembly condenses steam coming from the chamber back into water for re-use in the next cycle

PLASTIC RESERVOIR

The one-piece plastic reservoir (A) holds approximately4.5 quarts (4.25 liters) of water. The reservoir drain tube coonects to the quick connect on the front of the sterilizer.

WATER LEVEL INDICATOR

A white plastic float mechanism (B) located inside the reservoir activates the low water light on the front panel when water level in reservoir drops.

HEATING ELEMENT The heating element

There are no products to list in this category.

Categories

Important Links

- › For Missions Only

- › How To Repair Your Autoclave PC Control Board

- › OCM OCR Exploded View - UPDATED

- › Spore Test Failure

- › Sterilizer FAQ

- › Shipping Policy

- › Return/Cancellation Policy

- › Registered Trademarks

- › Disclaimer

- › Cleaning Statim Water Pump Filters

- › Payment Methods

- › International Customers

- › How To Test Autoclave Heating Elements

- › Testimonials

- › Can't Find The Door Gasket (Seal) You Need?

- › Used Autoclaves - What To Look For